- Alloy Steel – Quenched and Tempered

- Suitable for use with Grade 80 or Grade 100 chain

- All sizes are drop forged

- Individually proof tested to values shown with certification

- Proof tested with fixture sized to prevent localized point loading per ASTM A952

- Also available in links suitable for use at

-50 º F

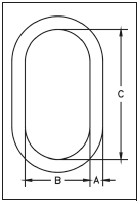

Master Link

| Size “A” (in.) |

A-342 Stock No. |

Working Load Limit (lbs.)* |

Proof Load (lbs.)** |

Weight Each (lbs.) |

Dimensions (in.) |

||

| B | C | Deformation Indicator |

|||||

| 1/2 | 1014262 | 7000 | 14000 | .82 | 2.50 | 5.00 | 3.00 |

| 5/8 | 1014280 | 9000 | 18000 | 1.52 | 3.00 | 6.00 | 3.50 |

| 3/4 | 1014306 | 12300 | 28400 | 2.07 | 2.75 | 5.50 | 3.50 |

| 7/8 | 1014315 | 15000 | 30000 | 3.50 | 3.75 | 6.38 | 4.50 |

| 1 | 1014324 | 24360 | 48700 | 4.85 | 3.50 | 7.00 | 4.50 |

| 1-1/4 | 1014342 | 36200 | 72400 | 9.57 | 4.38 | 8.75 | 5.50 |

| 1-1/2 | 1014360 | 54300 | 113200 | 16.22 | 5.25 | 10.50 | 6.50 |

| 1-3/4 | 1014388 | 84900 | 169800 | 25.22 | 6.00 | 12.00 | 7.50 |

| 2 | 1014404 | 102600 | 205200 | 37.04 | 7.00 | 14.00 | 9.00 |

| 2-1/4 | 1014422 | 143100 | 289200 | 54.10 | 8.00 | 16.00 | – |

| 2-1/2 | 1014468 | 160000 | 320000 | 67.75 | 8.00 | 16.00 | – |

| 2-3/4 | 1014440 | 216900 | 433800 | 87.70 | 9.50 | 16.00 | – |

| 3 | 1014486 | 228000 | 456000 | 115.00 | 9.00 | 18.00 | – |

| 3-1/4 | 1014501 | 262200 | 524400 | 145.00 | 10.00 | 20.00 | – |

| 3-1/2 | 1014529 | 279000 | 558000 | 200.00 | 12.00 | 24.00 | – |

| 3-3/4 | 1015051 | 336000 | 672000 | 198.00 | 10.00 | 20.00 | – |

| 4 | 1015060 | 373000 | 746000 | 228.00 | 10.00 | 20.00 | – |

| 4-1/4 | 1015067 | 354000 | 708000 | 302.00 | 12.00 | 24.00 | – |

| 4-1/2 | 1015079 | 360000 | 720000 | 345.00 | 14.00 | 28.00 | – |

| 4-3/4 | 1015088 | 389000 | 778000 | 436.00 | 14.00 | 28.00 | – |

| 5 | 1015094 | 395000 | 790000 | 516.00 | 15.00 | 30.00 | – |

*Minimum Ultimate Load is 5 times Working Load Limit. Based on single leg sling (in-line load), or resultant load on multiple legs with an included angle less than or equal to 120 degrees.

** Proof test load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9-1.4 for the chain size and number of legs.

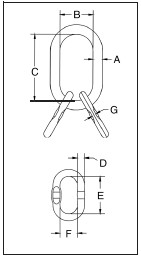

Master Link Assembly

| “A” Size (in.) |

A-345 Stock No. |

Working Load Limit (lbs.)* |

Weight Each (lbs.) |

Dimensions (in.) | ||||||||

| Based on Grade 8 Chain (4:1) |

Based on 5:1 Design Factor |

B | C | D | E | F | G | Deformation Indicator |

Engineered Flat for S-325A (in.) – (mm) |

|||

| 3/4 | 1014734 | 9100 | 12300 | 3.40 | 2.75 | 5.50 | .56 | 3.35 | 1.57 | .30 | 3.50 | 1/4″-5/16″, 7-8mm |

| 1 | 1014752 | 18400 | 24360 | 7.40 | 3.50 | 7.00 | .69 | 3.94 | 2.36 | .33 | 4.50 | 3/8″, 10mm |

| 1-1/4 | 1014770 | 31200 | 36200 | 15.90 | 4.38 | 8.75 | .88 | 6.30 | 3.54 | .53 | 5.50 | 1/2″, 13mm |

| 1-1/2 | 1014798 | 47000 | 54300 | 28.10 | 5.25 | 10.50 | 1.13 | 7.09 | 3.94 | .65 | 6.50 | 5/8″, 16mm |

| 1-3/4 | 1014814 | 73500 | 84900 | 46.00 | 6.00 | 12.00 | 1.38 | 8.00 | 5.00 | .73 | 7.50 | 3/4″, 20mm |

| 2 | 1014832 | 88900 | 102600 | 67.00 | 7.00 | 14.00 | 1.50 | 9.00 | 5.75 | – | 9.00 | No Flat |

| 2-1/2 | 1014850 | 123900 | 160000 | 142.00 | 8.00 | 16.00 | 2.00 | 14.00 | 7.00 | – | – | No Flat |

| 2-3/4 | 1014859 | 188000 | 216900 | 196.0 | 9.50 | 16.00 | 2.25 | 16.00 | 8.00 | – | – | No Flat |

| 4 | 1014995 | 373000 | 403.4 | 10.00 | 20.00 | 2.75 | 16.00 | 9.50 | – | – | No Flat | |

*Ultimate Load is 5 times the Working Load Limit. Based on 60 degree included angle or smaller. For included angles greater than 60 degrees, the Working Load Limit must be de-rated.